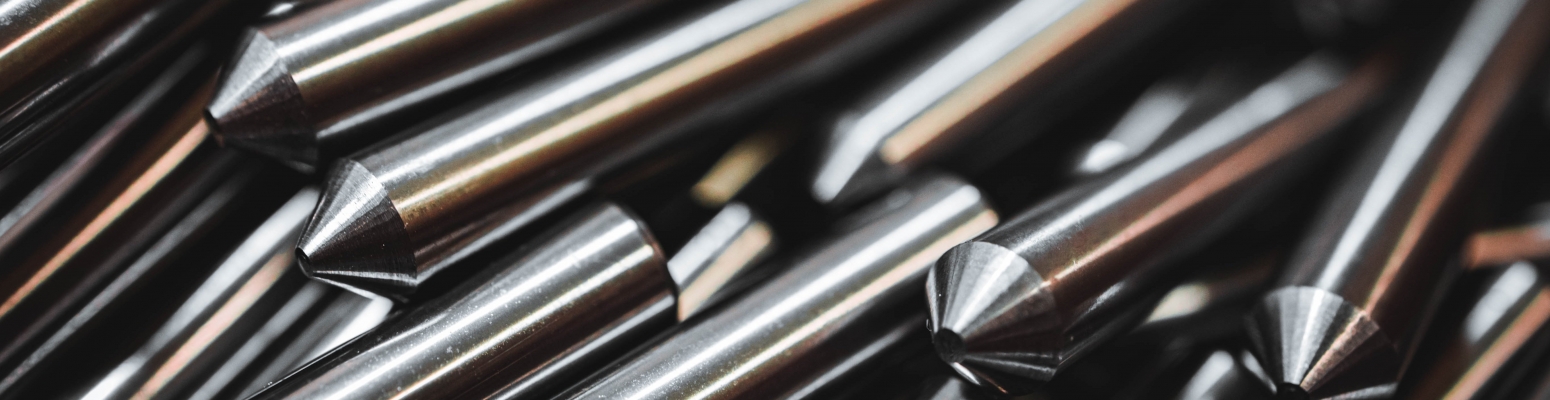

Why and How to use carbide tap

Maximizing Efficiency with Carbide Taps in Precision Threading

Features of Carbide Tap

Carbide taps offer a variety of advantages in tapping operations, particularly when dealing with abrasive materials.

Carbide is known for its durability, flexibility, and longevity, which can lead to reduced tool replacement, less downtime, and increased productivity. Two areas where carbide or carbide tipped taps should be considered are high production applications in non-ferrous and medium and low carbon steels. High RPM’s and a rigid setup is essential to good performance. The second is Nickel and other alloys with a high hardness, making the use of Steel taps impractical (HRC 40+).

Here are some different types of carbide taps and when to use them:

Solid Carbide Spiral Point Taps

ACT Spiral point carbide taps are made from the finest micro grain carbide and are designed to cut steel as well as non-ferrous materials. Hook angles achieved assist in the free cutting of hard and abrasive materials.

Application: Those with Long Chip, Blind Hole or Thru Hole is recommended to use this type.

Solid Carbide Straight Flute Tap and Hand Tap

ACT Hand Taps features for its long-lived carbide. Eliminate the need for frequent tool changes, making them the economical choice for long production runs. Product ranges: Metric size, UN, Pipe Parallel and Pipe taper thread.

Application:

Material with short chip and thru hole is recommended.

Hand tap is most efficient on hard work pieces such as titanium alloys, stainless steel, hardened material

Solid Carbide Roll Form Tap

This type of tap are flute-less. The thread form is lobed so there are a finite number of points contacting the work. This tap does not cut, so it is ‘chip-less’ and, consequently, will not cause a chip problem. The tool forms the thread by extrusion, thus thread size can be closely maintained. The flute-less design allows high-quality threads, faster tapping speeds, higher production, and generates no chips, which simplifies tapping of blind bottoming holes

Application: Can be use in both Thru and Blind hole, materials such as Alumiumn 6061-T6, ADC, Soft Steel, Iron, Titanium Alloy, Copper pipe, Tool Steel and Stainless Steel.

Custom Made Tap, Thread Mills and Cutting Dies

Interrupted thread, Brazed Carbide taps,

DIN/ JIS Shank

Cutting Dies or Tap Chaser,

Different type of Cut: Left hand and Right hand cut tap is available.

Internal and External Thread

Other

-

27.Sep.2023

Carbide Threading Tools