What is a Chamfer?

What is a Chamfer?

A chamfer is a flat, angled cut usually made at 45 degrees along the edge of an object to remove sharp corners, making it safer and easier to handle or assemble.

It can be used on metal, wood, plastic, and concrete.

What is the purpose of a chamfer?

Chamfering has several important benefits in manufacturing and product design:

- Reduce Stress: Remove sharp corners, reducing the chance of cracks, breaks, and fatigue.

- Improve Safety: Getting rid of sharp edges makes parts safer to handle.

- Increase Durability: Less stress on corners means parts last longer and are more reliable.

- Make Assembly Easier: Chamfered edges make it easier to fit parts together smoothly.

- Improve Appearance: Chamfers give a neat, polished look, making products more visually appealing.

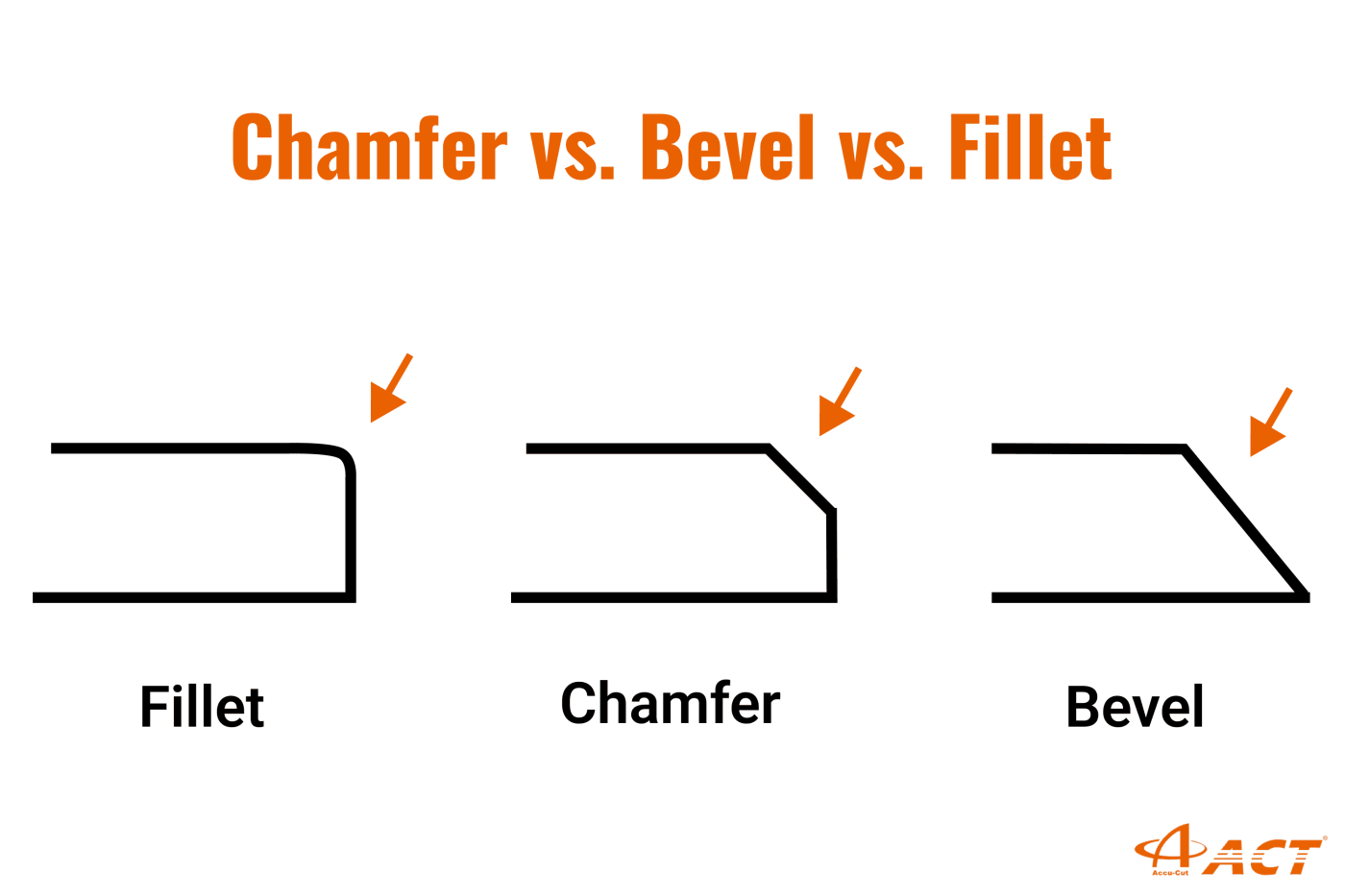

Chamfer vs. Bevel vs. Fillet: What are the Differences?

Chamfer, Bevel, and Fillet are different ways to modify edges, each with its own purpose:

- Chamfer: Flat, angled cut, usually at 45 degrees.

- Bevel: Sloped cut at any angle along an edge.

- Fillet: Rounded edge or corner.

Chamfer vs. Bevel vs. Fillet Comparison Chart

| Feature | Chamfer | Bevel | Fillet |

|---|---|---|---|

| Definition | Flat, angled cut at an edge or corner | Sloped cut along an edge | Rounded or curved edge or corner |

| Angle | Typically 45° | Any angle | Rounded, not specified by angle |

| Purpose | Safety, ease of assembly, aesthetics | Fit, aesthetics, joining parts | Stress reduction, smoother transitions |

| Typical Use | Edges and corners of workpieces | Full length of an edge or surface | Corners for a smooth finish |

| Applications | Machining, woodworking, general product design | Welding, frames, decorative purposes | Machining, product design, ergonomic features |

| Common Tools | Chamfer end mill | Beveling tool, plate beveler | Radius cutter, fillet tools |

What is a Chamfer mill?

A chamfer end mill is a high-precision cutting tool ideal for CNC machining.

It performs external chamfering, internal hole chamfering, and V-groove milling at angles like 30°, 45°, or 60°.

Why use a Chamfer mill?

- Precision and efficiency: Perfect for CNC machining, providing high accuracy and suitability for large-scale production.

- Versatility: Capable of chamfering, deburring, countersinking, and beveling.

- Material Compatibility: Works well with steel, aluminum, and heat-treated materials.

How to use a chamfer end mill: 7 steps

Step 1: Check your tool

Make sure your chamfer tool is ready to use:- Drill a small pilot hole.

- Insert the tool, make a shallow cut, and measure the width of the chamfer to check the tool’s sharpness and flatness.

Step 2: Know your Depth-to-Width ratio

Chamfer tools usually follow a simple rule:- For sharp tools, the width of the chamfer is twice the depth (e.g., 200 units deep = 400 units wide).

- If the tool has a flat tip, you’ll need to adjust the depth slightly to account for it.

Step 3: Align the tool

Set up your tool properly:- Position it on the centerline of your part and make sure it’s touching the surface evenly.

- Zero your measurements (on CNC or manual machines) so you have a baseline.

Step 4: Adjust for flat tips

If your tool isn’t perfectly sharp:- Subtract the flat tip size from the depth you plan to cut.

- Test small cuts and adjust to avoid overcutting or damaging your part.

Step 5: Test the setup

Use a marker to color the edge of the part:- Gradually lower the tool and look for the marker to be removed, showing the chamfer is forming.

- Make small adjustments as needed.

Step 6: Cut the chamfer

Once everything is set:- Move the tool to the desired spot, lower it to the right depth, and create the chamfer.

- If you’re using a CNC machine, input the tool’s offset diameter to ensure consistent cuts.

Step 7: Double-check your work

After cutting:- Measure the chamfer width with calipers or a gauge.

- Compare it to your design to ensure it meets the required specifications.

Best chamfer end mill for your budget and needs

When selecting the best chamfer end mill for your needs, it's essential to understand each product's features, strengths, and limitations.

Here’s a straightforward comparison of three popular chamfer end mills: SpeTool Chamfer End Mill, Speed Tiger Chamfer End Mill, and ACCU CUT I2DMS Chamfer End Mill.

SpeTool Chamfer End Mill

Price: $14.99

Price: $14.99

Key Features:

- Angle: Offers 30° - 90° with a 1/4" shank, suitable for a variety of woodworking and metal applications.

- Material: Solid carbide with TiAlN coating, great for cutting hardwood, softwood, plywood, and metals up to HRC 55.

- Versatility: The 4-flute V-bit design allows for high-speed cutting with a clean surface finish, ideal for engraving, sign making, and chamfering.

Best For: Woodworkers, especially those looking for a budget-friendly option.

SPEED TIGER Chamfer End Mill

Price: $15.40 - $38.99

Price: $15.40 - $38.99

Key Features:

- Angle: Available in different angles for a range of materials, including wood, aluminum, steel, and cast iron.

- Coating: ZrN + AlTiBN coating offers heat resistance, enhancing stability during high-temperature cutting.

- Material: Made from micrograin carbide, ensuring toughness and durability.

Best For: General machining chamfering.

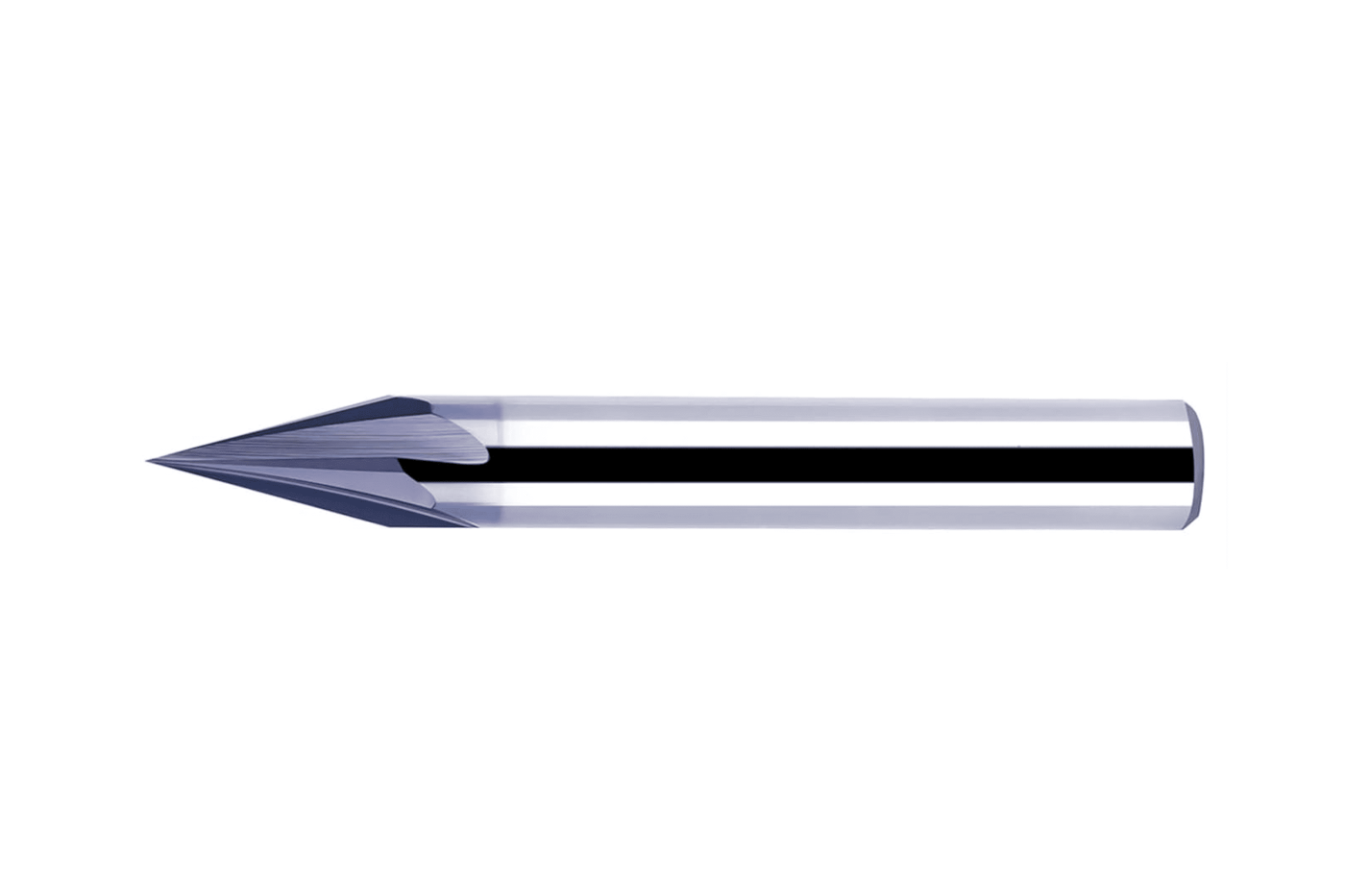

ACCU CUT I2DMS Chamfer End Mill

Key Features:

- Angle Flexibility: Available in 15°, 30°, 45°, and 60° angles, providing great flexibility for different chamfering and engraving applications.

- Material: Made from ultra-fine grain carbide, with high wear resistance and enhanced tool life, makes it ideal for high-volume and precision CNC machining.

- Coating: Features AlTiCrN coating, ideal for dry machining.

- Customizability: The adjustable size and angle options make it suitable for a wide variety of tasks.

- Multi-Functionality: The tool can be used for chamfering, spotting, deburring, and side milling, reducing the need for frequent tool changes.

Best For: Professional machinists who require precision and versatility,and looking for a tool that can handle multiple functions and different materials .

FAQ

Is a chamfer always 45 degrees?

No, a chamfer is not always 45 degrees. While 45° is the most common angle used, chamfers can also be created at other angles such as 30° or 60°.

What is a chamfer used for?

A chamfer is used to smooth sharp edges on parts, making them safer, easier to assemble, and more visually appealing.

What is the difference between a chamfer mill and a countersink?

A chamfer mill is used for making angled edges on the outside or edges of a part, while a countersink is used to create a cone-shaped hole so screws or bolts fit flush with the surface.

Chamfer Mills Are Only for Chamfering?

No, chamfer mills are versatile tools that can also be used for deburring, edge finishing, and even light V-groove cutting. Some chamfer mills can also handle side milling tasks.

Are More Chamfer Angles Always Better?

No, most chamfering needs can be satisfied with a 45-degree angle. Having too many angle options can increase tool management costs.

Chamfer Accuracy Relies Only on the Tool?

No, Machining accuracy depends not just on the tool, but also on factors like machine rigidity, cutting parameters, and workpiece stability.

For example, spindle runout or an unstable workpiece can lead to uneven chamfer depth and poor final results.

Are chamfer mills easy to break?

No, tool breakage is often due to overloading or insufficient cooling, rather than a flaw in the tool itself.

High-quality chamfer mills are built with wear-resistant properties to withstand long-term machining.

Can chamfer mills replace all chamfering tools?

No, chamfer mills are best for automated machining, and manual chamfering tools are better suited for tight spaces or small parts.